Nuts by Specialinsert®

Specifically designed for applications on thin panels, the cage nuts allow you to arrange removable threaded venues within a pre-punched square hole. In addition to allowing repositioning, these systems, unlike threaded holes, can be replaced in case of damage due to excessive screw tightening. Intended to be used on electric cabinets and racks, they are also ideal for maintenance on old-generation equipment.

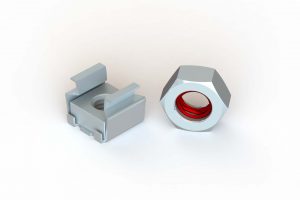

Cage-Nut is the Specialinsert® proposal dedicated to such uses: the system consists of a framework nut enclosed in an elastic metal cage, which allows a certain freedom of movement, thus eliminating misalignment games in the assembly. The insertion in the punched seat is done by manual compression of the wings present on the cage, available in steel or stainless steel materials, also for the nut, chosen according to the specific needs.

Inside the Specialinsert® nuts line for solid bodies stands out, however, Filtec-Nut, the self-blocking nut that has inside a thread reported braked Filtec®. The main advantage of this system is the ability to eliminate copycats, counterdades and elastic washers, as well as adhesives and sealants. The blocking of Filtec-Nut is, in fact, guaranteed by the warped coils of the reported thread braked and, by virtue of its perfect symmetry, the screwing can take place from both sides.

Resistant to dynamic loads, vibrations and shocks, the system retains the self-locking effect even after repeated unscrewing and screwing. Finally, the high temperature resistance, i.e. up to 600°C depending on the material chosen, makes Filtec-Nut an ideal solution for the motor industry.