Additive Manufacturing and Fastening Systems: An Evolving Challenge

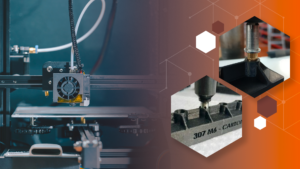

The rapid evolution of additive manufacturing and 3D printing is revolutionising the way industrial components are designed and produced. This advanced technology offers unprecedented design freedom, enabling the creation of lightweight, complex, and highly customised structures. However, as with any technological innovation, new challenges emerge, particularly regarding fastening systems.

One of the key challenges lies in the vast amount of multimedia content shared across social media channels, often lacking clarity and professional approaches, especially when it comes to fastening solutions for 3D-printed components. This is precisely why 3NTR and Specialinsert have collaborated to provide professionals with reliable data and professional fastening solutions.

3D-printed components require specific fastening solutions that have to be carefully evaluated in order to adapt to different materials.

It is within this context that the collaboration between 3NTR, a leading manufacturer of professional 3D printers, and Specialinsert®, a benchmark in innovative fastening systems, was established. Two Italian companies, deeply rooted in the Made in Italy manufacturing culture, came together to share their technological expertise and provide professionals with accurate data and cutting-edge solutions.

Together, they initiated a testing campaign to identify the most effective fastening solutions for certain 3D-printed materials, offering industry professionals certified and reliable data.

3NTR and Specialinsert®: A Partnership of Innovation and Quality

3NTR: From Traditional Manufacturing to Excellence in 3D Printing

3NTR is an Italian company with over 60 years of manufacturing experience, continuously evolving to meet the increasingly complex demands of the market. In 2013, the company entered the world of 3D printing to proactively address an internal production need, demonstrating its commitment to innovation.

An Innovation Journey Shared with Specialinsert

3NTR’s mission is to deliver high-performance, precise, and reliable industrial 3D printers, capable of tackling the industry’s most complex challenges. This philosophy perfectly aligns with Specialinsert®, a company that has been designing and producing highly innovative and efficient fastening systems for decades.

Specialinsert® aims to establish itself as an innovative and ever-evolving company, capable of developing customised, technologically advanced solutions, while also offering cutting-edge services.

With a shared commitment to quality, research, and customer satisfaction, this collaboration was a natural evolution for both companies.

Through this joint project, 3NTR and Specialinsert® combined their expertise to test and validate fastening solutions specifically designed for 3D-printed materials, ensuring certified data for components produced via additive manufacturing.

Fastening Systems and Additive Manufacturing: Testing Process

To provide a comprehensive analysis, the tests focused on two materials with opposite properties, commonly used in 3D printing:

- Carbon+ – A carbon-fibre reinforced composite material developed by 3NTR for maximum mechanical strength and structural rigidity.

- ABS (Acrylonitrile Butadiene Styrene) – A widely used thermoplastic polymer, known for its flexibility and impact resistance. It is softer and more versatile than its predecessor for 3D printing.

The tests aimed to evaluate the mechanical performance of two Specialinsert fastening systems, analysing their tensile strength, torque resistance, and ease of installation.

Fastening Solutions Tested

Insert-Plast®

A threaded expansion insert, designed to withstand high tensile and torsional loads. The double-crown version was selected for the tests to ensure maximum material adhesion.

- Installation: The insert is positioned using press-fit installation, expanding when the screw is inserted to anchor securely to the hole walls.

- Benefits: This system generates a self-locking effect, enhancing the joint’s long-term stability.

Ensat® 307

A self-tapping metal bush with internal and external threads, specifically designed for low-resistance materials such as plastics, composites, and reinforced polymers.

- Installation: The insert self-taps into the material, creating a wear-resistant threaded seat.

- Benefits: Ideal for thin sections, it allows for quick and cost-effective installation, ensuring high mechanical performance even in challenging conditions.

The test results provided valuable insights into how fastening systems interact with different 3D-printed materials, equipping engineers and manufacturers with essential data to optimise component design and enhance fastening reliability in additive manufacturing.

Innovation and Research & Development

This case study highlights the significance of collaboration between leading companies across different industrial sectors. The partnership between 3NTR and Specialinsert® demonstrates how continuous research and experimentation can drive the development of advanced fastening solutions for additive manufacturing.

Specialinsert’s approach to Research & Development is encapsulated in its motto, “Passionate About Innovation”, which guides the company in developing cutting-edge fastening systems for the most challenging applications.

Discover more about Specialinsert’s commitment to R&D and innovation: Visit our Research & Development page